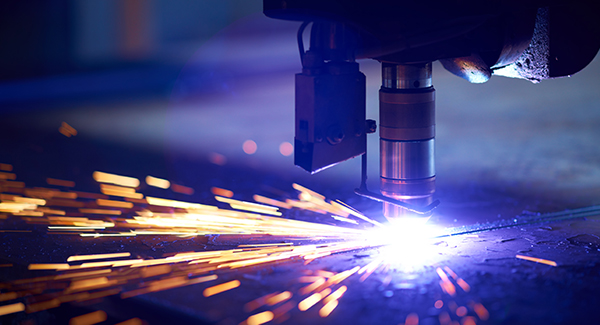

Achieve next-generation performance for laser, waterjet and plasma metal-cutting machines. Optimize the fieldbus, control loop bandwidth, servo motor design, feedback system and cabling using these 5 motion tips for high-precision metal cutting.

The exoskeleton market is still in its infancy — but evolving quickly and ripe with opportunity. It’s a double-edged sword for OEMs who must identify the most impactful applications and crack the code on full-scale production, which presents a new…

Missile systems continue to evolve to meet specialized needs — from tactical guided missiles to longer-range strategic weapons, each designed for launch from a particular platform to reach a particular target. Defense contractors are under pressure…

When specifying servo motors, drives and cables, learn how to optimize motion by incorporating mechanical load, motion profile, ambient environment, cabling and other considerations into a system-wide approach.

The food processing and packaging industry plays a major role in ensuring that the final product is safe to consume. While food safety is a serious requirement, it also presents significant challenges for manufacturers. Frequent, high-pressure…

Humanoid robots promise to make life and work better for millions of people. But creating a design that performs tasks with human-like dexterity and superhuman endurance, then bringing it successfully to market, means solving multiple design…

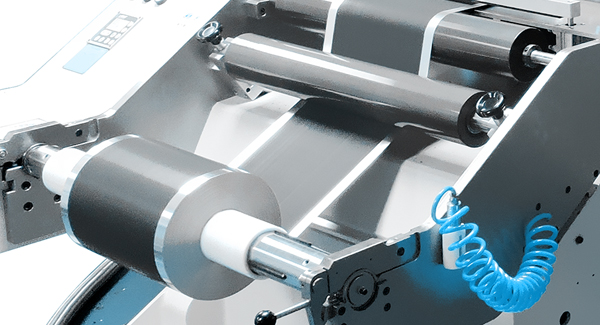

Direct drive technology improves the manufacturing quality and productivity of lithium-ion batteries used in battery-electric vehicles and other products that are changing the world.

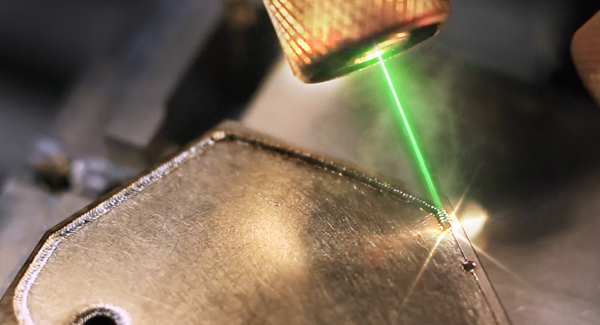

One important stage in manufacturing lithium-ion batteries for electric vehicles is seal-welding the positive-terminal top cap to the battery shell. Laser welding is the ideal technology for this purpose, but it requires precise motion, speed and…

The accepted principle of matching motor to load inertia is no longer pertinent with today’s faster processors and advanced control algorithms.

Discover how Kollmorgen optimizes the size, weight and power density of motion solutions to help UAVs fly longer and farther for greater mission success.

When correctly sizing AC servo motors, it’s important to avoid miscommunication issues. Learn the critical terminology around sizing that leads to safe, reliable operation.

As electric vehicles promise cleaner, more sustainable transportation, the need for reliable lithium-ion batteries is skyrocketing. Battery manufacturers are looking for innovative ways to maximize production quality and speed.