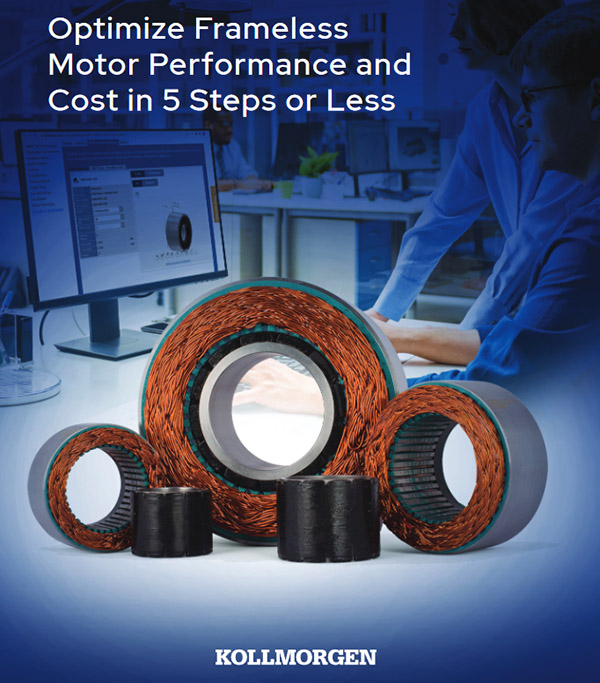

Kollmorgen TBM Frameless Motor Selection Guide

The TBM frameless motor is a series of direct drive torque motors designed for applications that require high power in a small, compact form factor with minimized weight and inertia. Typical applications include robotic joints, weapon stations, sensor gimbals, sight systems, UAV propulsion and guidance, as well as many others. Download the selection guide to learn more.